Bio Compost

Use of Chemical Fertilizers seriously impair the soil fertility. If high concentrations of Chemical fertilizers are applied to the soil, the natural nutrients of the soil are imbalanced thereby effecting soil fertility.

The gainful use of bio-manure can help address this threat. “Green Samrudhi” is major source of organic carbon to the soil besides being rich in NPK(Nitrogen-Phosphorus-Potassium)

Green Samrudhi -

Press mud a residue left over from sugarcane after extraction of juice is used with spent wash an effluent, which is a waste of distillery for the production of Organic Fertilizer.

The group has installed the Bio Compost Plant near factory site. which is marketed under the brand name “Green Samrudhi”.

Composting Process -

Composting Process: Churning and turning process with aero tiller.

Spent wash :Auto spraying machine

- Press Mud is dumped at the site.

- Making triangular shaped rows known as windrows..

- Spent wash is sprayed on each windrow at specific intervals.

- Windrows so formed are regularly turned with an Aero tiller(Compost Turner). This helps in maintaining uniform temperature and moisture with effective aeration and oxygen supply.

- Microbial culture is broadcasted on the windrows by Aero tiller by turning the windrows to accelerate microbial activity during process.

- During the composting process, the temperature goes up to 65-70° C .

- In order to maintain temperature of the windrow to about 40°C (for thermophillic reaction) water is spread while simultaneously while turning the windrows.

- Bacteria separate carbon and other complex compounds from press mud and spent wash.

- The windrow product is regularly analyzed for various parameters which are moisture %,pH, Carbon and Nitrogen % during process.

- The process of turning windrows and water spraying is continued for about 30 to 40 days.

- The blackish brown material in the form of organic manure is ready for its use, after carrying out sieving process , the product is packed in requisite bags(Double layer Polythin bags).

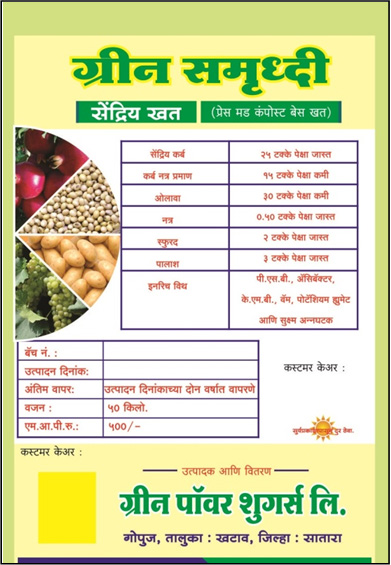

Specifications of Green Samrudhi -

Composting Process: Churning and turning process with aero tiller.

Spent wash :Auto spraying machine

- Organic Carbon: More than 25%

- Carbon Nitrogen ratio: Less than 15 %

- Moisture Content: Less than 30%

- Nitrogen: More than 0.50 %

- Phosphorous: More than 2%

Benefits of using Green Samrudhi -

- Improves water retention capacity of the soil.

- Improves the soil structure, porosity, density and air circulation of the soil, thus creating a better plant root environment.

- Improves friability(workability), porosity and gas & water permeability thus reducing erosion of soil.

- Modifies and stabilizes pH of the soil.

- Supplies variety of micro and macro nutrients.

- Supplies significant quantities of the organic matter.

- Improves cation exchange capacity of soils and growing media, thus improving there ability to hold nutrients for plant use.